Tech Insights: Digital Twins – The Future of Simulation and Design

Introduction

In an era driven by data and real-time intelligence, Digital Twins have emerged as one of the most transformative technologies across industries — from aerospace and manufacturing to healthcare and smart cities.

A Digital Twin is a virtual representation of a real-world object, process, or system that mirrors its physical counterpart through continuous data synchronization.

It allows engineers, designers, and operators to simulate, analyze, and optimize performance before making real-world changes.

Put simply, digital twins make it possible to test ideas in the digital world before applying them in the physical one.

What Is a Digital Twin?

A Digital Twin integrates IoT data, machine learning models, and real-time analytics to create a living model that evolves as its physical counterpart changes.

It goes beyond static 3D models — it’s a dynamic, data-driven replica that reflects actual behavior under varying conditions.

Example:

An engine manufacturer uses a digital twin of a jet turbine to monitor sensor data, predict maintenance needs, and optimize fuel efficiency — all without interrupting real-world operation.

Core Components of a Digital Twin

| Component | Description |

|---|---|

| Physical Object or System | The real-world asset being represented (e.g., a building, vehicle, or machine). |

| Digital Model | A virtual 3D model or simulation of the object. |

| Data Connection | IoT sensors, telemetry, and edge devices stream data in real time. |

| Analytics Engine | ML and AI algorithms process incoming data to detect anomalies or predict outcomes. |

| Visualization Interface | Dashboards, AR/VR tools, or CAD systems that display performance insights. |

Together, these components create a feedback loop — data from the physical asset updates the twin, and insights from the twin influence real-world decisions.

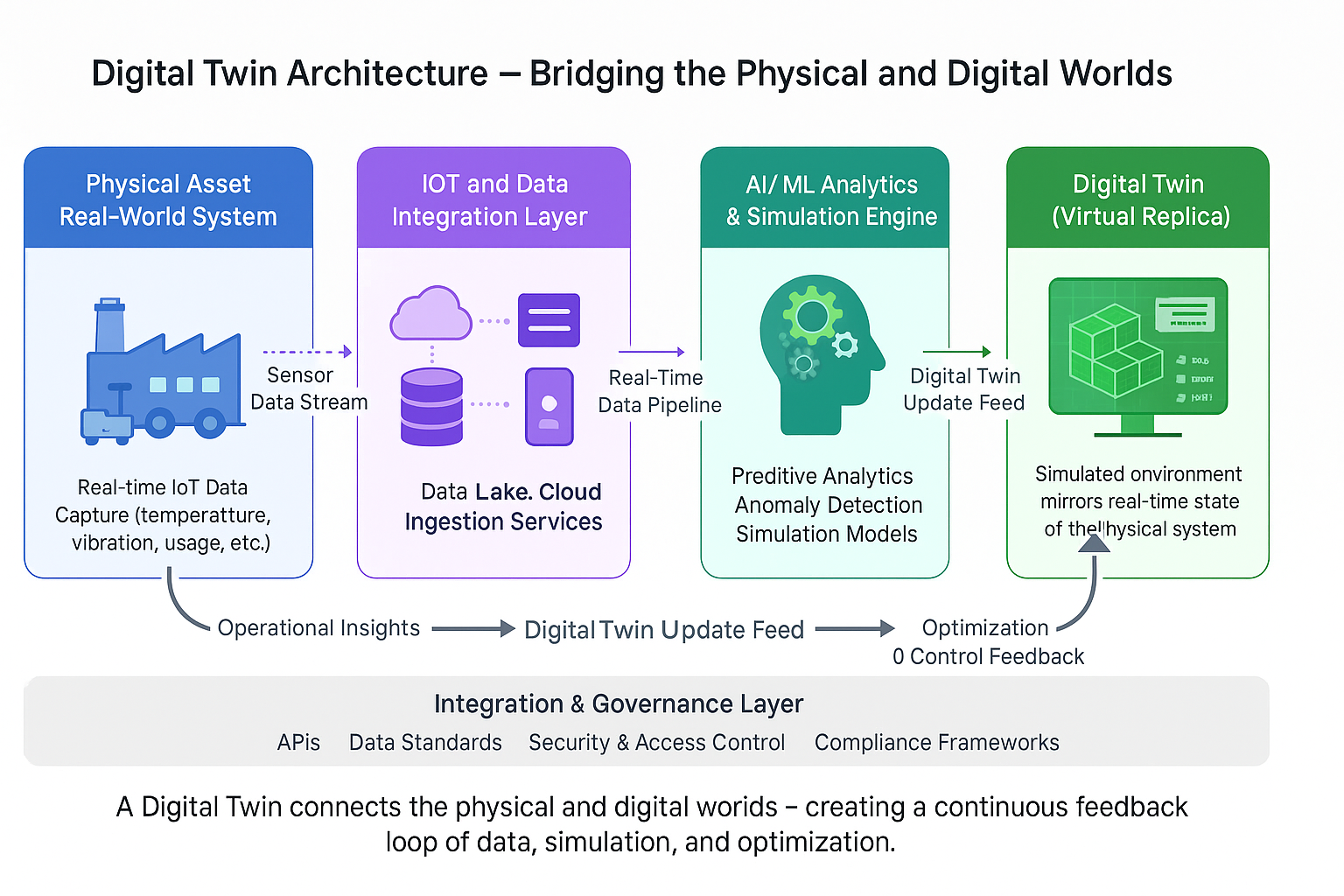

How Digital Twins Work

- Data Collection: Sensors and IoT devices collect metrics such as temperature, vibration, or pressure.

- Integration: Data is transmitted to cloud platforms (e.g., AWS IoT TwinMaker, Azure Digital Twins).

- Modeling: The system builds a digital model using simulation tools and physics-based modeling.

- Analysis: AI and ML algorithms analyze patterns, predict outcomes, or test design variations.

- Feedback: Insights are sent back to the physical system for optimization or corrective action.

This continuous loop ensures real-time synchronization between the digital and physical worlds.

Digital Twin Architecture – Bridging the Physical and Digital Worlds

Figure: Digital Twin Architecture – Bridging the Physical and Digital Worlds

Types of Digital Twins

| Type | Purpose |

|---|---|

| Component Twin | Represents a single part or sensor (e.g., engine blade). |

| Asset Twin | Models an entire piece of equipment or system (e.g., a car engine). |

| Process Twin | Simulates workflows or manufacturing processes. |

| System Twin | Models the interactions between multiple assets (e.g., a production line). |

| City Twin | Represents entire infrastructure systems — buildings, traffic, and energy networks. |

As complexity grows, twins evolve from individual components to entire ecosystems — forming a Digital Thread that connects data across lifecycle stages.

Applications Across Industries

1. Manufacturing

Digital twins enable predictive maintenance, quality control, and performance optimization.

Factories simulate equipment operation under varying loads to prevent downtime and optimize output.

2. Smart Cities

Urban planners use digital twins to model traffic flow, energy distribution, and environmental impact, enabling data-driven infrastructure decisions.

3. Healthcare

Hospitals are creating patient digital twins to simulate treatment outcomes, monitor recovery, and personalize care.

4. Aerospace and Automotive

Aircraft and vehicle manufacturers run simulations on digital replicas to improve design, safety, and fuel efficiency — long before prototypes are built.

5. Energy and Utilities

Energy companies leverage digital twins to manage grid performance, forecast demand, and simulate renewable energy flow.

Benefits of Digital Twin Technology

- Reduced Costs: Simulations prevent costly trial-and-error in the physical world.

- Improved Reliability: Continuous monitoring helps detect issues before failures occur.

- Faster Innovation: Engineers can test new ideas virtually and iterate quickly.

- Better Decision-Making: Real-time analytics improve planning, logistics, and operations.

- Sustainability: Optimized resource consumption reduces waste and emissions.

Challenges and Considerations

Despite its potential, implementing digital twins comes with challenges:

- Data Integration Complexity: Synchronizing data from multiple sensors and systems is non-trivial.

- High Computational Demand: Real-time simulation requires robust cloud and edge infrastructure.

- Security and Privacy: Continuous data streams from physical assets must be securely managed.

- Interoperability: Integrating tools from different vendors demands open standards.

Overcoming these requires strategic design, secure connectivity, and scalable computing architectures.

Tools and Platforms for Building Digital Twins

| Platform | Description |

|---|---|

| AWS IoT TwinMaker | Enables creation of digital twins with real-time IoT and 3D visualization. |

| Azure Digital Twins | Comprehensive platform for modeling complex environments and systems. |

| Siemens NX & MindSphere | Combines CAD design and industrial IoT analytics. |

| PTC ThingWorx | Industrial-grade IoT and simulation platform. |

| Dassault Systèmes 3DEXPERIENCE | Focused on design, simulation, and lifecycle management. |

These tools allow seamless integration between design, simulation, and real-world feedback loops.

The Future of Simulation and Design

The next generation of digital twins will integrate AI, edge computing, and real-time simulation engines, enabling near-instant feedback loops across systems.

Expect innovations like:

- Autonomous optimization: Twins that self-correct operations without human intervention.

- Cross-domain simulation: Linking product, process, and environment twins for holistic modeling.

- Immersive design: Engineers interacting with twins in AR/VR environments for live design adjustments.

In the future, every physical system will have a digital counterpart, continuously learning and improving from its own data.

Conclusion

Digital Twins represent the convergence of IoT, AI, and simulation — transforming how we design, build, and operate systems.

They allow organizations to move from reactive operations to predictive, data-driven decision-making, unlocking efficiency and innovation.

In short, digital twins don’t just simulate the world — they help reshape it.

No comments yet. Be the first to comment!